Separation methods for different industries

We provide research data for application to separation processes such as adsorption, crystallization, chromatographic separation, membrane separation, and pressure filtration.

We conduct research for the needs of the mining industry, metal processing, the pulp and paper industry, the chemical industry, the food industry, the pharmaceutical industry and future biorefineries, as well as many other sectors.

Take advantage of scientific research opportunities and feel free to contact us.

Sami Virolainen

Expand your networks and participate in public projects!

State of the art facilities and experimental infrastructure

Water treatment plant upgrades

We develop separation and purification methods, which enable the updating of the water purification plant to be a raw material source. Possible products are for instance nutrients, proteins and pure water. We also develop processes to improve the removal of micropollutants, such as drug residues, heavy metals and microplastics.

Mari Kallioinen-Mänttäri

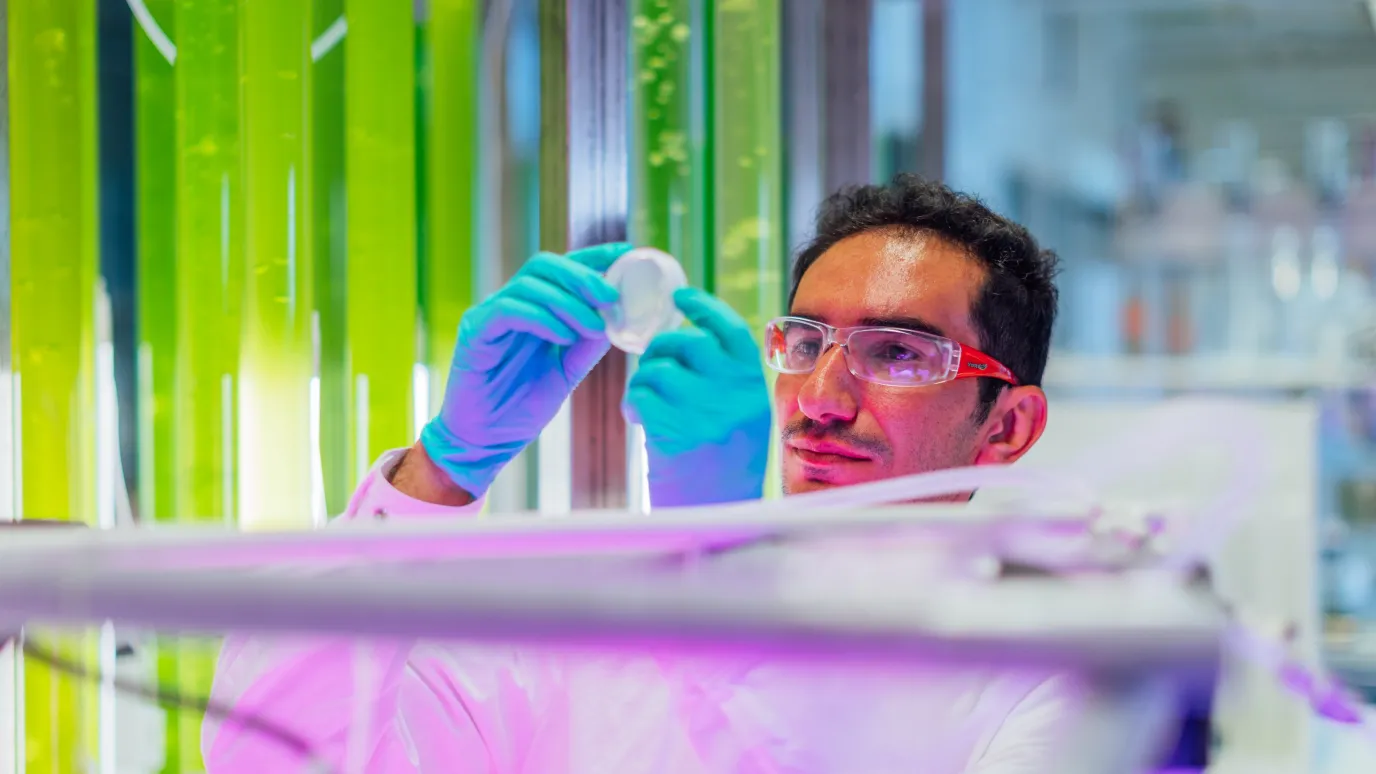

New applications of algae technology

Water Treatment and Algal Biotechnology Lab in Mikkeli at LUT’s separation science department investigates the potential of commercial as well as Nordic strains of microalgae and microalgal consortia for wastewater treatment, CO2 biofixation, nutrients recovery and production of value-added products such as bioplastics and biofuel from algal biomass.

The lab is equipped with different types of photobioreactors and an open raceway pond for mass cultivation of algae.

The research output of the lab continuously adds to the growing knowledge base of microalgal biorefinery and circular bioeconomy research.

New business in the circular economy of metals

Regarding metals circular economy in Department of Separation Science research is done in for example following separation technologies: ion exchange, liquid-liquid extraction, solid-liquid separation, adsorption, electrochemical separation technologies and membrane technology. From societal point of view the topics include currently battery and energy metals separations and utilization of secondary raw materials to metals production.

The researchers in circular economy of metals work for the publicly funded and contract research projects in close co-operation with companies.

The laboratories are located mostly at Lappeenranta Campus in which there are equipment for laboratory scale experiments on fundamental phenomena such as equilibrium and kinetics on most of the industrially relevant unit processes in metals refining. In addition, the Department of Separation Science has industrial-type separation equipment for these unit processes. The workstations contain automation and instrumentation for online monitoring and controlling the separation processes.

Sami Virolainen

Hydrogen economy and utilization of renewable energy forms in future energy solutions

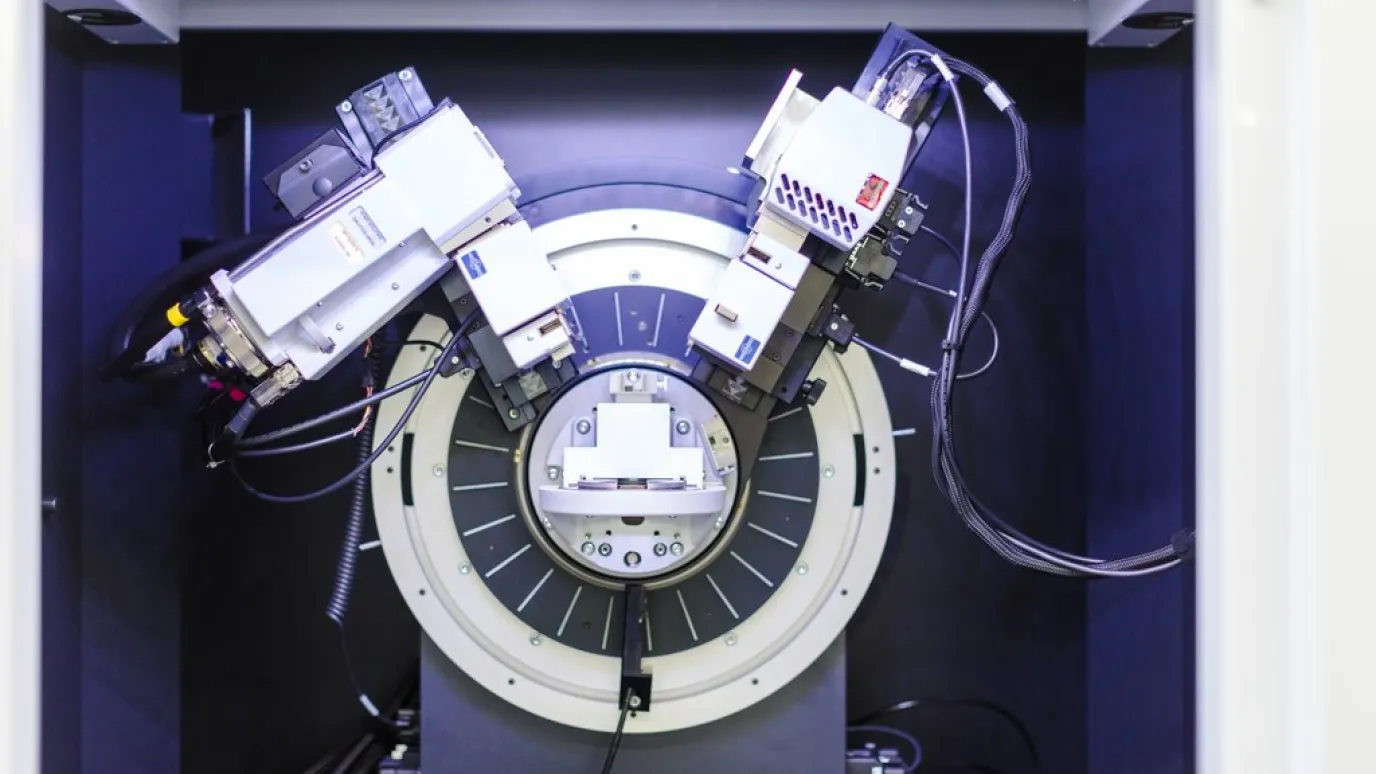

Chemical Process Systems engineering- research group has in central role PtoX-chemicals and fuels production technologies research, where Process Intensification methodology is used to intensify product yields, energy savings, and to minimize investment costs of plant units.

Our research methods are based on laboratory scale experiments and experimental data, which is mainly used for physico-chemical process modeling and simulation in design of production processes. We have in lab different type of reactors and separation technologies, where instrumentation and in-line/off-line analytics can be coupled. We use both commercial and “in-house” software in process modeling. In detailed process equipment simulations computational fluid dynamics tools are utilized. They give a strong basis for preliminary design of production processes in addition with CAPEX and OPEX calculations.

Current research topics are not only methanol synthesis research and carbon capture and utilization, but also production process development of chemicals and fuels from renewable natural resources.

Tuomas Koiranen

Utilisation of forest biomasses

We develop advanced processes and understanding to enable resource efficient utilisation of forest biomasses to ensure sustainable materials to production of our every-day products. We develop more techno-economically feasible and sustainable processes. We do this by enhancing separation unit operations in the processes, electrifying heating and with more efficient integration of the processes to other industry. Our knowledge covers both the recovery of the valuable compounds from biomass and separation, purification and concentration of them for further use. In addition, we have knowledge on utilisation of forest-based biopolymers in production of several materials and products needed in our every-day life. In addition to the understanding on unit operations, we also have knowledge on plant and mill design.

Mari Kallioinen-Mänttäri