Brie description of the invention

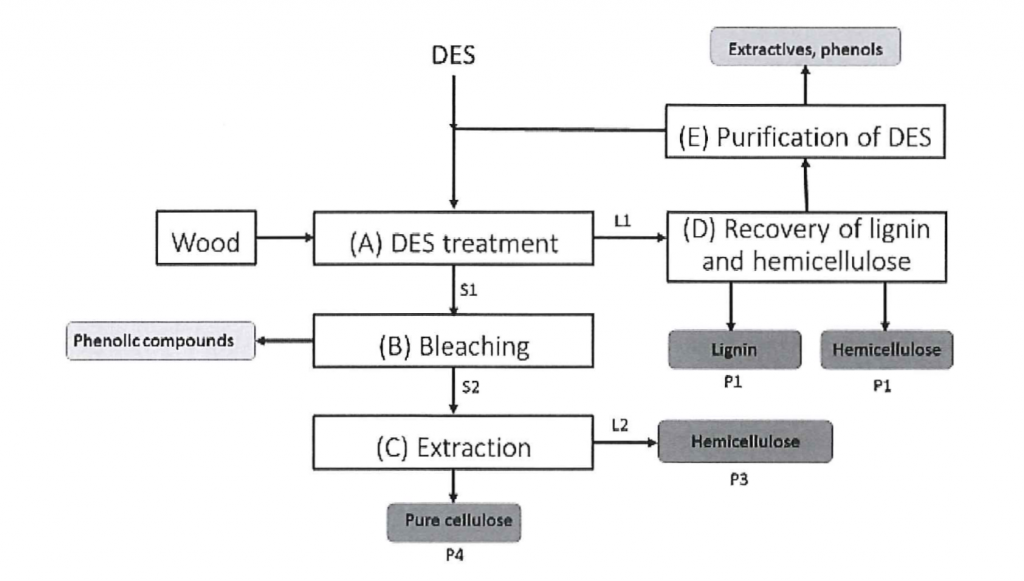

Novel fractionation process enables purification and recovery of wood polymeric compounds as relative pure fractions. Process is based on several stages which together create a process which give high purity fractions of wood polymers such as cellulose, hemicellulose and lignin. In this process novel deep eutectic solvents (A in the figure below) are utilised with bleaching (B) and different extraction (C) and separation technologies to produce purified fractions of wood polymers.

Purified cellulose (P3) has well known use in textile industry or as raw material for production of cellulose derivatives. These are applications were dissolving pulp produced by prehydrolyses kraft process or sulphite process including cooking stage and several bleaching stages are used today. Purified sulphur free Iignin (P1) and hemicelluloses (P2) are not currently available in larger amount. These fraction can be used as polymers or feedstock to bio-conversion or chemical conversion processes.

The first stage of the process is wood treatment with deep eutectic solvents (DES). This is intensively studied treatment in the literature. In this stage significant amount of lignin and a smaller amount of carbohydrates (hemicellulose) is dissolved (L1). Totally about 40% of the dry solids is dissolved in DES treatment. Dissolved compounds in DES i.e. lignin and hemicelluloses are separated by membrane filtration and/or precipitation processes and residual DES is purified for reuse. The purified product fractions P1 (lignin) and P2 (hemicellulose) are produced.

Solid fraction (S1) from DES treatment consist of mostly cellulose and hemicellulose and minor amount of lignin. The residual lignin is removed from solid material in bleaching stage (B). This can be done even in one bleaching stage e.g. with sodium chlorite (NaClO2). A DES treatment prior to bleaching significantly improves the bleaching efficiency and simplifies the bleaching process. Without DES treatment 4 or 5 bleaching stages is needed to achieve the same residual lignin content in the solid fraction. Therefore, less bleaching stages and chemicals are needed when the wood is first treated by DES.

After bleaching the solid fraction consist of cellulose and hemicellulose (S2). Hemicellulose can be extracted with alkaline extraction or with hot water and the residual solid material consist of mainly cellulose. The purity of extracted hemicellulose is remarkably higher than achieved in pressurized hot water extraction of wood chips or saw dust. Therefore, its further purification and concentration for instance by membrane filtration is feasible.

Attachments

Lisää aiheesta

Licensing contact

Tero Lehikoinen