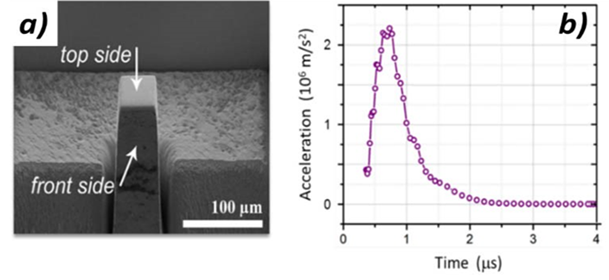

The potential of MSMAs to transform electromechanics has been compared to how silicon revolutionised electronics. As starters of this field, the research group focuses on the development and creation of smaller, more reliable, and cost-effective actuating and sensing devices, paving the way for innovative applications such as novel microfluidic devices, soft robotic actuators, and micro-magneto-mechanical systems (MAMS). In MAMS, functional components such as pumps, manifolds and fluidic channels are integrated in an MSM material chip in a way analogous to electronics components and electric leads are integrated in a semiconducting material chip. MAMS chips take advantage of ultrafast actuation of the MSMAs. Figure below shows an MSMA (Ni-Mn-Ga) micropillar (a) (http://urn.fi/URN:ISBN:978-952-335-305-3) and its actuation acceleration of even 2 million m/s2 (b) by an applied magnetic field pulse.

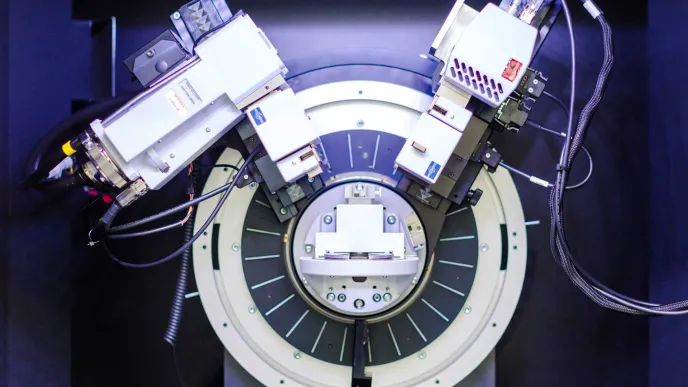

The MAMS chips are micromachined using a femtosecond pulse laser ablation setup installed in our laboratory. We have the required equipment for characterisation of the manufactured materials and devices, including a specialised microbeam x-ray diffractometer, high-resolution x-ray diffractometer, polarised light microscopes, electromagnets, scanning electron microscope, atomic/magnetic force microscope, laser Doppler vibrometer, ultra-high-speed video camera and magneto-mechanical testing devices.

Project manager

Research areas

The research portfolio of the group includes the exploration of fundamental magneto-mechanical phenomena in MSMAs, the development of alloying strategies to enhance their properties, and the application of various manufacturing techniques, including additive manufacturing (3D and 4D printing), single-crystal growth, pulsed laser micromachining, and casting. These efforts are supported by the group’s advanced materials characterisation capabilities, which allow a deeper understanding of material properties and behaviours. New applications for MSMAs are also being actively developed.

Infrastructure

In addition, research on magnetocaloric materials, which promise to revolutionise refrigeration systems, is being advanced in LUT Material Physics Laboratory. These materials offer the potential to improve cooling capacity while eliminating the need for harmful liquid refrigerants that contribute to climate change. A key approach of the group is focused on achieving higher efficiency in synthesising and testing novel material compositions, promoting shorter lead times from conceptualisation to production.