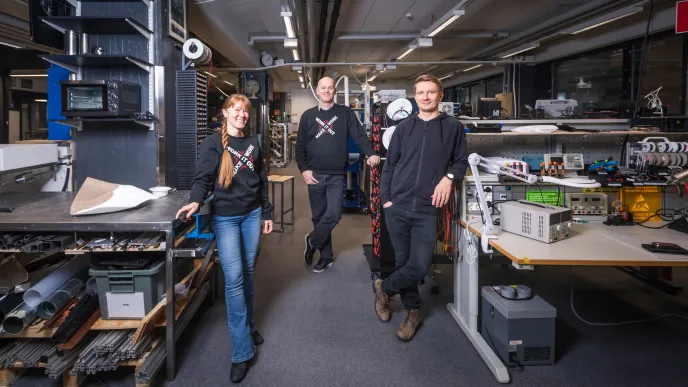

The need for satellites, the problem of orbital debris, research stations and possible human colonies – these are only a few of the many space-related issues with which people on Earth are occupied. Also LUT University’s JHC Challenge is aiming for outer space in 2023. LUT’s prototype lab JHC, the Finnish Science Center Heureka, and the sawmill industry digitalization company Finnos are challenging students to develop structures for use in outer space.

The materials in the first prototype round are low-cost and easy to process. JHC’s Project Manager Terhi Virkki-Hatakka explains that the testing phase can involve materials such as paper, cardboard, wood and fabric to show how parts fit together or how a structure opens or closes. Outer space, however, requires materials that withstand cold, heat, radiation and weightlessness – depending, of course, on whether the materials are meant for use in a spacecraft or outside it.

The student entries for the JHC Challenge include one that focuses on the disposal of space debris, three or four on the promotion of astronauts’ health in outer space, and two on construction in space. Specifically, students have submitted ideas such as a full-body compression suit, a sleep mask for space, and producing threaded tubes on an ultrasound surface in orbit.

Minna Palmroth, professor of computational space physics at the University of Helsinki, states: ”Space is as hot a topic as it was in the late 1960s with the race to put a man on the moon.” There is a significant shortage in specialists in the field, as space research could help solve issues on Earth as well.

”JHC does not do marketing for student work, but students are free to commercialize their own ideas themselves. In previous JHC Challenges, student ideas have been commericialized through programs such as LUTES Forward,” Terhi Virkki-Hatakka relates.

LUTES is a student-led entrepreneurship community for LUT and LAB students.

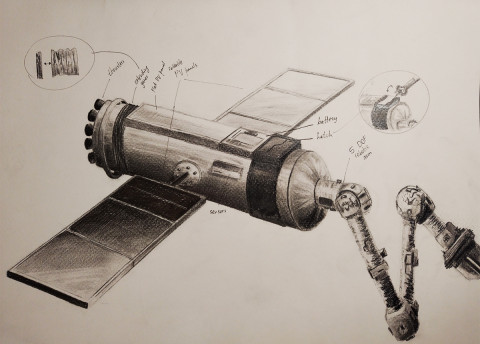

Debris-collecting satellite

"Our idea is to build a conceptual model of a satellite that collects debris in space. The debris can be any particles, large pieces of broken satellites or other thrash that can potentially damage satellites currently orbiting the Earth. The debris-collecting satellite is supposed to be placed in low Earth orbit and gather particles one by one using a robotic arm. The satellite would also store the particles.

Originally, our idea was supposed to be an in-orbit autonomous recycling station, but it got simplified into something we can build considering limitations both in time and budget.

The first step would be to create a precise 3D model to ensure everything works as expected and we do not waste any materials. After that, we would simply start building and putting the pieces together. Lastly, we have to program the whole system, which is usually the hardest thing. However, it should not take us long since it is a simple robotic arm and foldable panels along with a compressing system. The task is challenging, but we will come up with better systems for the application.

From my point of view, the construction of the compressing system (that decreases the volume of thrash inside) and the system to make the satellite expand laterally will be the most difficult parts. Deciding where to dispose of the debris will also take some time. Since we do not have billions in government funding like NASA does, we will create a smaller model using materials available to us, such as plywood, aluminum sheets, acrylic, 3D-printed parts, servo/stepper motors for the arm, solar panels, batteries, microcontrollers, and other pieces of hardware."

Sergey Vorobey, student in Technology and Engineering Science Bachelor's programme

Student projects may end up in Heureka’s exhibition

The idea for a space-related JHC Challenge came from Heureka. The science center is currently planning a space exhibition that will open in February 2024.

Heureka became interested in collaboration with JHC when Jamie Hyneman became LUT’s professor of practice. The JHC Challenge provided a convenient opportunity for cooperation.

”The storytelling space exhibition enables visitors to carry out tasks with the help of space industry specialists, such as researchers in different fields, technology experts, or even a space law specialist,” lists Sami Pihkala, exhibition producer at Heureka.

Whether or not outcomes from the JHC Space Challenge will be featured in Heureka’s space exhibition remains to be seen. The prototypes must be especially sturdy because visitors will be able to test the devices themselves, and most visitors will be children. Virkki-Hatakka says this sets certain requirements for items in the exhibition. ”If the space challenge submissions include ideas that fit the Heureka exhibition, visitor-proof versions can be made,” she points out.

Finnos wants to engage with students

Virkki-Hatakka says JHC was hoping to collaborate with Finnos already in early 2022 in connection with the previous JHC Challenge that dealt with environmental issues. However, COVID restrictions still got in the way, and collaboration was postponed.

Finnos sells artificial intelligence-based measurement services to the sawmill industry. The company is the world-leading manufacturer of log x-ray systems. Even though Finnos’s business is based firmly on Earth, the company wanted to sponsor the JHC Space Challenge.

”We like to do good deeds whenever we can. This allows us to connect with the university and engage with students. Being involved in the challenge aligns with our desire to pioneer in development and pursue predominance in our industry,” explains Jere Heikkinen, CEO of Finnos.

Although Finnos will not be able to utilize the student ideas in the JHC Challenge directly, Heikkinen states: “If the competition entries utilize augmented or virtual reality, they could be applied to our activity in some way.”

Full-body compression suit

"I came up with the idea by reading articles about everyday life on the ISS. I figured that given the timeframe and budget, it would be best to improve an existing solution than to solve a current problem without a solution. My first idea was a sleeping bag that helps ventilation and reduces noise for sleeping, but the solutions to this seemed too trivial. I wanted more of a challenge. I then learned that astronauts can lose one percent of their bone mass per month, even when they exercise regularly. I decided to try to reduce this loss.

The task itself will be somewhat difficult but also straightforward. The problem of compressing the bones axially can be accomplished easily using straps, but the hardest part will likely be maintaining as axial of a force as possible. If the bone is compressed with more force on one side than the other, it could bend the bone and do more harm than good. Thus, the optimization of the force application will be the most challenging part of the design.

The first steps in the project will be to research options for the flexible fabric suit that will act as the frame of the design, select the optimal material for the bracing components, and secure all materials and components. The material for these bracing components must be strong enough to withstand the force in the straps and also light enough.

One might assume that weight is irrelevant for an item used in space, but heavier objects require more fuel to get into space. As such, the material used will likely be either wood or plastic. The next stage after material selection and component acquisition will be optimization of the bracing component design and testing thereof."

Jake Cumens, Master's student in Mechanical Engineering, JHC assistant

JHC Challenge

◼ The sparring and selection panel consists of LUT’s Professor of Practice Jamie Hyneman and representatives of the prototype lab JHC, science center Heureka and digitalization company Finnos Oy.

◼ LUT’s prototype lab JHC provides facilities and tools for building the prototypes. Finnos offers financing.

◼ The evaluation criteria included light weight, durability, and ease of opening and assembly. In addition, feasibility and the so-called wow factor were also considered.

◼ Jamie Hyneman will help the student groups to develop their ideas and implement their solutions in the 2023 spring semester.

More information: