As the leading research and education unit in its field in Finland, the LUT Welding Technology offers extensive and versatile research and education modules in welding technology as well as influences society by providing the most recent knowledge and expert services to its industry partners.

Research and education topics of LUT Welding Technology

- digitized welding and welding production

- intelligent welding

- advanced welding processes and equipment

- adaptive welding, control and feedback

- arc welding processes, e.g., SMAW, GMAW, GTAW, PAW, SAW

- hybrid processes, e.g., laser-GMAW, laser-SAW

- WAAM (wire-arc-additive-manufacturing)

- mechanized and robotized welding

- productivity, profitability and efficiency of robotized welding

- modelling and simulation of robotized welding

- welding quality and its management

- quality management and control

- welding coordination

- destructive and non-destructive testing

- overall development of welding production

- quality and lead time

- productivity and cost-efficiency

- welding networks

- welding management

- welding metallurgy and weldability

- high-strength and ultra-high-strength steels

- stainless steels

- aluminums

- arctic conditions

Infrastructure

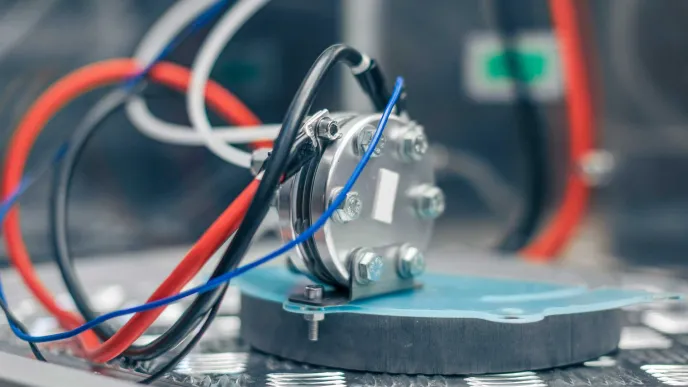

The research environment at the LUT Welding Technology enables material weldability studies and the testing and analysis of the metallurgic and mechanical properties of welded joints. The modern research devices are employed to examine the applicability of processes to different application targets and help to optimize productivity and efficiency by evaluating the quality and mechanization of welding. The robotized welding environment enables weldability studies and the testing of individual joints, components, structures or entire products and different simulation and remote programming studies.

Equipment:

- wide-ranging and up-to-date welding equipment

- mechanization and robotized welding stations (ABB and Yaskawa)

- simulation and remote programming softwares

- optical sensors and robotized measurements

- scanning and analysis of welded joints

- devices for testing materials in different conditions

- NDT (non-destructive testing)

- DT (destructive testing)

- metallography devices (microscopy/macroscopy)

- OES alloy analyses

- heat treatment equipment

Group members

Tuomas Skriko

Sakari Penttilä

Antti Martikainen